Location:Home > Comprehensive > System management

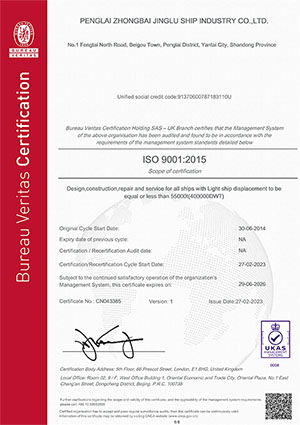

JLS has established a quality management system in accordance with the requirements of the GB/T19001-2008 quality management system, and passed the ISO9001:2008 quality management system in 2008. With the revision of the quality management system standards, JLS has developed and issued new versions of the "Quality Manual" and "Quality Management System Procedure Documents", and implemented them accordingly. JLS completed the certification change audit of the ISO9001:2015 version of the quality management system in 2017.

In order to ensure the normal and effective operation of JLS 's quality management system, JLS primordially has formulated a series of quality management system documents, mainly including the "Quality Manual", "Quality Management System Procedure Documents", and "Quality Management Operation Documents". It has also formulated systems such as the "Management Rules for Internal, External, Patrol and External Inspection", the "Quality Supervision and Management Assessment Rules", the "Non destructive Testing Work Process", and the "Three Level Inspection System", to ensure the continuous improvement of product quality, the goal of achieving a one-time pass rate of over 93% for internal quality inspection, over 94% for external quality inspection, over 97% for UT, and over 90% for RT has been achieved.

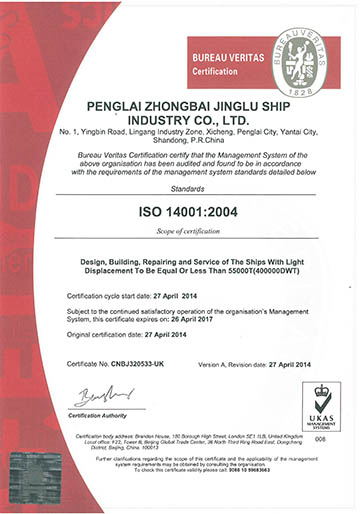

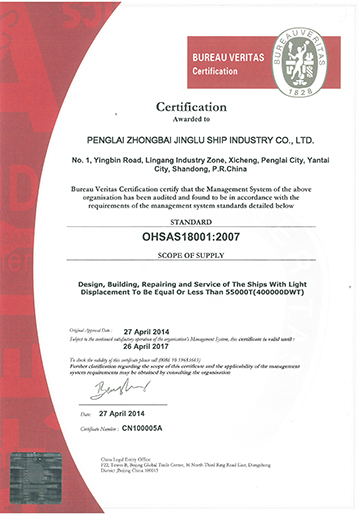

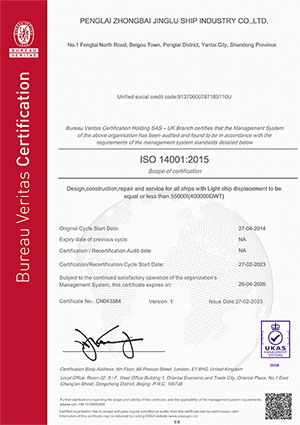

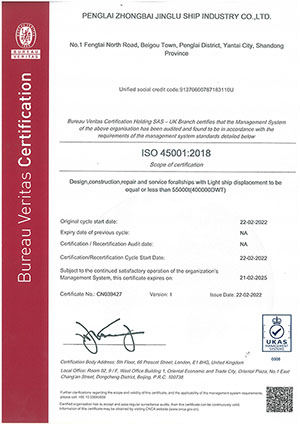

In order to ensure JLS 's safety production, JLS initially successfully obtained environmental management system and occupational health and safety management system certifications in 2014, and passed the certification through annual system revision audits according to relevant requirements. In terms of safety production management, JLS strictly establishes and improves the safety production responsibility system in accordance with laws and regulations, establishes a safety production committee, establishes a safety management organization, and equips full-time safety management personnel. Regular safety production meetings, safety hazard investigation, safety training, etc. are held to achieve full participation and management. At the same time, a company level safety production emergency plan is also developed, and employees are regularly organized to conduct emergency rescue drills based on the plan content to improve emergency processing capabilities

Environmental Management System Certificate ISO14001:2004(English)

Management System Certificate ISO9001:2008(English)

Occupation Health Safety Management System Certificate OHSAS18001:2007(English)